The salmon fillet process requires a high standard of hygiene because people and equipment are in direct contact with the raw material that will be ingested by the final customer.

Therefore, we developed a high-quality product, according to the standard of food safety, minimizing the risk of contamination.

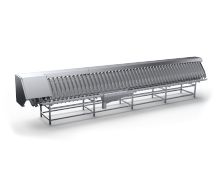

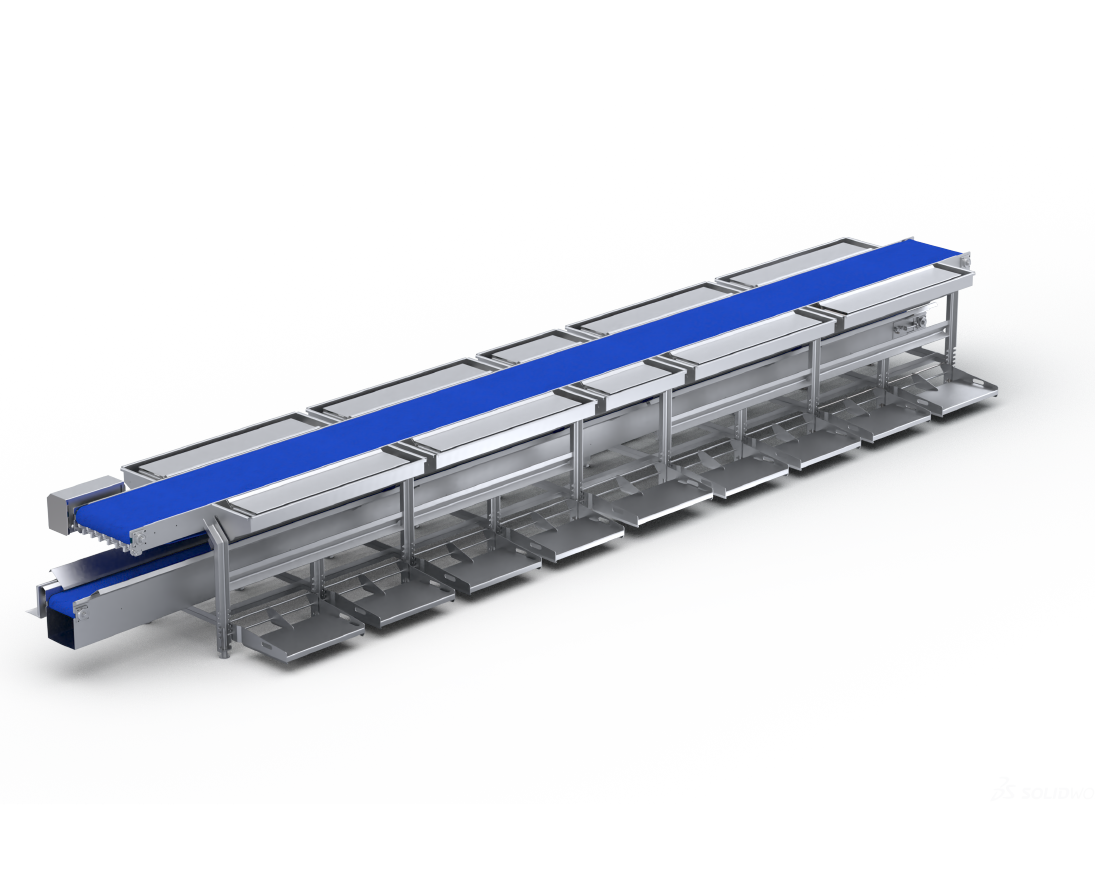

Our fillet lines are designed to efficiently evacuate waste, minimize the use and accumulation of water, and make cleaning as easy as possible.

- Hygienic anti-bacterial design.

- Thermodrive-type sanitary band (or similar).

- Design based on stainless steel plates (without closed profiles).

- Countertops and pivotable hoppers allow cleaning in all sectors.

- Minimal support legs.

- Transfer between belts with a special plate (minimum friction).

- Worktable allows waste to be disposed on the entire edge, eliminating rubbish on the floor.

- Closed waste conveyor allows waste and water to be extracted by vacuum, without accumulation in the process room.

- Possibility of installing a rotary filter before the waste hopper (optional).

- In-situ belt lifting system, allows washing without dismantling.

- Made of stainless steel, designed for long useful life.

- Adjustable individual footboards.

- Sanitary ending (sandblasted with glass microspheres).

RELATED PRODUCTS